Gears for Surgical Robotics

Precision Engineering Driving Medical Innovation

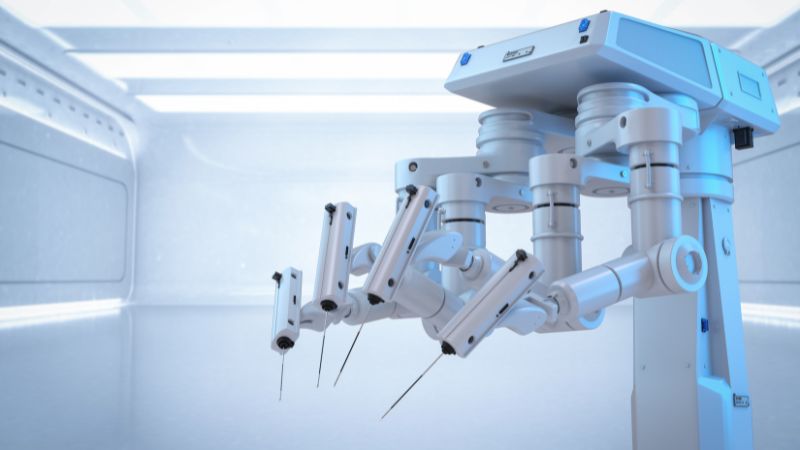

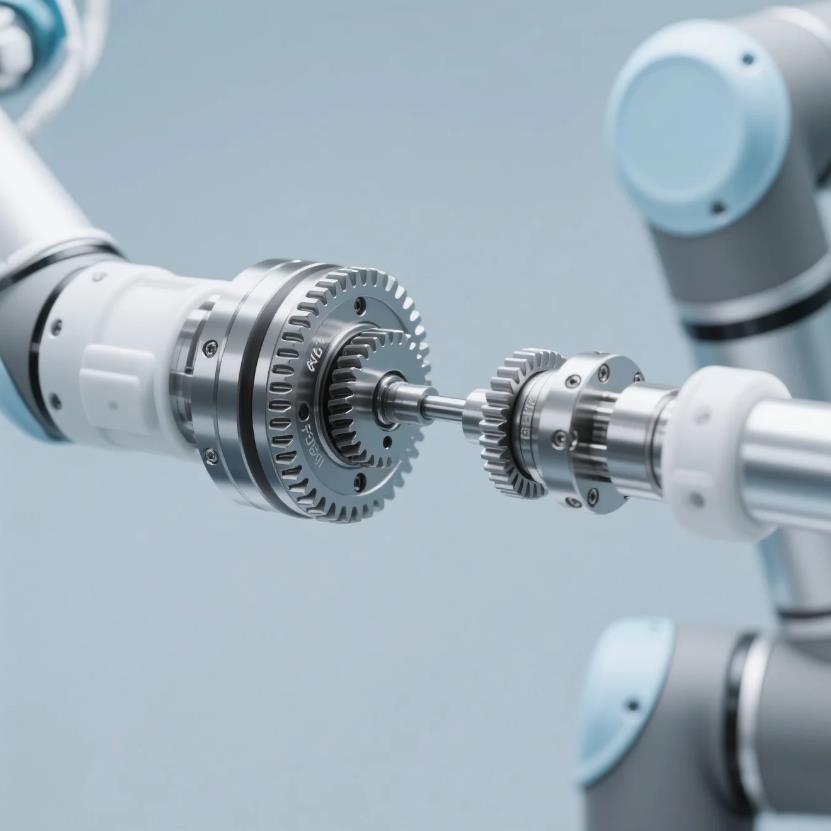

Surgical robotics represents one of the most significant breakthroughs in modern medical technology, revolutionizing how surgeons perform complex procedures with enhanced precision and control. At the heart of these sophisticated systems lies a crucial component often overlooked: high-precision gears. These mechanical elements enable the smooth, accurate movements essential for life-saving procedures, combining cutting-edge engineering with medical expertise.

From planetary gear systems that power robotic arms to miniaturized worm gears facilitating precise instrument positioning, gears are the unsung heroes enabling surgeons to extend their capabilities beyond human limitations. This page explores the critical role of gear technology in surgical robotics, highlighting how advancements in gear design and manufacturing directly translate to improved patient outcomes.

Evolution of Surgical Robotics

Surgical robots have undergone remarkable development since their inception, with each generation bringing significant improvements in precision, functionality, and clinical applications. The evolution of gear technology has been central to these advancements.

The PUMA 560 system marked the first application of robotic technology in surgery, used primarily in neurosurgical procedures. These early systems featured basic gear mechanisms with limited precision and degrees of freedom.

The introduction of the da Vinci Surgical System revolutionized minimally invasive surgery. This system incorporated advanced planetary gear systems and helical gears, enabling more precise movements and better control, significantly reducing patient trauma and recovery times.

Specialized surgical robots emerged for specific procedures, featuring customized gear configurations optimized for particular surgical applications. Gear manufacturing techniques improved significantly, allowing for higher precision and durability.

Integration of advanced materials in gear manufacturing, including medical-grade titanium alloys and specialized polymers. Haptic feedback systems were developed, requiring even more sophisticated gear arrangements to transmit tactile information to surgeons.

Modern surgical robots feature AI integration, machine learning capabilities, and real-time decision support systems. Today's systems utilize ultra-precision gears with micron-level tolerances, often manufactured using advanced techniques like Metal Injection Molding (MIM) and Direct Metal Laser Sintering (DMLS).

Key Benefits of Surgical Robots in Modern Medicine

Surgical robots have transformed medical procedures, offering numerous advantages over traditional surgical approaches. The precision engineering of their gear systems directly contributes to these benefits:

Enhanced Surgical Precision

Enhanced Surgical PrecisionSurgical robots equipped with high-precision gear systems can perform movements with sub-millimeter accuracy, eliminating hand tremors and enabling microsurgical procedures beyond human capabilities. This precision is crucial in delicate operations involving vital structures like nerves, blood vessels, and sensitive tissues.

Minimally Invasive Approach

Minimally Invasive ApproachThe compact gear arrangements in robotic instruments allow for smaller incisions and less tissue disruption. Patients experience reduced pain, lower infection risks, decreased blood loss, shorter hospital stays, and faster return to normal activities—all stemming from the ability of precision gears to translate large movements into small, controlled actions.

Expanded Surgical Capabilities

Expanded Surgical CapabilitiesAdvanced gear systems enable robotic instruments to reach anatomical areas traditionally difficult to access in conventional surgery. The dexterity provided by multi-stage gear reductions allows for complex maneuvers in confined spaces, expanding the range of operable conditions and anatomical sites.

Improved Ergonomics for Surgeons

Improved Ergonomics for SurgeonsGear-driven control systems reduce surgeon fatigue by translating hand movements into precise instrument actions without requiring awkward postures. The mechanical advantage provided by gear systems allows surgeons to perform longer, more complex procedures with less physical strain and maintained concentration.

Telesurgery Possibilities

Telesurgery PossibilitiesHigh-performance gear systems with minimal backlash are essential for remote surgical applications, where command signals must be precisely translated into physical movements. These systems facilitate expert surgical care in underserved locations and potentially even extreme environments like space missions or disaster zones.

Improved Procedural Outcomes

Improved Procedural OutcomesThe consistency and reliability of gear-driven movements lead to more standardized procedures with predictable results. Clinical studies demonstrate reduced complication rates and improved long-term outcomes across numerous surgical specialties using robotically-assisted approaches.

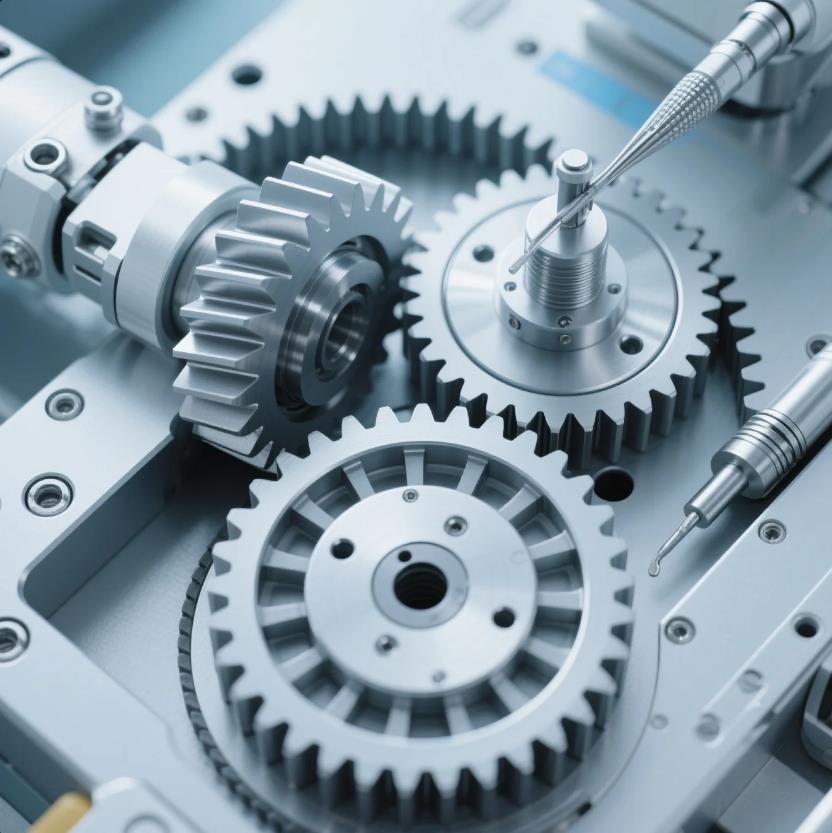

Essential Gear Types in Surgical Robotics

The precision, reliability, and performance of surgical robots depend heavily on specialized gear systems designed to meet the unique demands of medical applications. Each gear type serves specific functions within the robotic system:

Planetary Gear Systems

These compact, high-torque transmission systems are fundamental to surgical robotic arm movement and control. Key advantages include:

- High torque density in a compact package

- Excellent power transmission efficiency (>95%)

- Precise motion control with minimal backlash

- Even load distribution across multiple gear teeth

- Primary application in robotic arm joints and main drive systems

Medical-grade planetary gears often utilize specialized materials like titanium alloys or high-performance polymers to meet sterilization requirements while maintaining precision.

Helical Gears

These gears feature teeth cut at an angle to the face of the gear, providing several benefits critical to surgical applications:

- Exceptionally smooth and quiet operation

- Gradual tooth engagement reducing vibration

- Higher load-carrying capacity than straight spur gears

- Excellent for continuous operation during lengthy procedures

- Often used in instrument rotation mechanisms and precision control systems

Modern surgical robots utilize custom-designed helical gear sets with optimized helix angles to balance smoothness with axial thrust management.

Bevel Gears

These conical gears transmit power between intersecting axes, essential for the complex articulation of surgical instruments:

- Enable 90-degree (or other angle) power transmission

- Critical for wrist-like movements in robotic end effectors

- Available in straight, spiral, and hypoid configurations for different applications

- Facilitate complex multi-axial movements in confined spaces

- Enable the miniaturization of articulating instrument tips

Spiral bevel gears are particularly valuable in surgical robots due to their smoother operation and higher contact ratio compared to straight bevel gears.

Worm Gear Systems

These gear arrangements provide unique advantages for specific surgical robot functions:

- Inherent self-locking capability for maintaining position

- Extremely high reduction ratios (20:1 to 300:1) in a single stage

- Smooth, precise movement ideal for fine adjustments

- Right-angle power transmission in compact spaces

- Commonly used in instrument positioning systems and locking mechanisms

Advanced surface treatments and specialized lubricants have overcome traditional worm gear efficiency limitations for medical applications.

Specialized Gear Applications in Surgical Systems

Beyond the primary gear types, surgical robotics employs numerous specialized gear configurations to address specific functional requirements:

Advanced Materials in Surgical Robot Gears

The unique requirements of surgical applications have driven the development of specialized materials for gear manufacturing:

| Material | Key Properties | Applications |

|---|---|---|

|

Medical-Grade Stainless Steels (17-4PH, 316L) |

Corrosion resistance, sterilization compatible, good wear resistance | General-purpose gears in non-patient-contact applications |

|

Titanium Alloys (Ti-6Al-4V ELI) |

Exceptional strength-to-weight ratio, biocompatibility, non-magnetic | MRI-compatible systems, weight-critical applications |

|

PEEK (Polyether Ether Ketone) |

Self-lubricating, lightweight, excellent chemical resistance | Low-load applications, gear systems requiring autoclave sterilization |

|

Nickel-Titanium Alloys (Nitinol) |

Superelasticity, shape memory, biocompatibility | Specialized compliant mechanisms, adaptive gear systems |

|

Ceramic Components (Zirconia, Silicon Nitride) |

Extreme hardness, wear resistance, non-magnetic | High-precision bearing surfaces, wear-critical components |

Surface treatments and coatings further enhance gear performance in surgical environments:

- DLC (Diamond-Like Carbon) Coatings: Provide exceptional wear resistance and low friction, extending gear life in continuous-use surgical systems

- Passivation Treatments: Enhance corrosion resistance for components exposed to biological fluids or sterilization chemicals

- Antibacterial Surface Treatments: Emerging technologies incorporating silver or copper ions to reduce infection risks

Recent Technological Advances

The field of surgical robotics continues to evolve rapidly, with gear technology playing a central role in many key innovations:

AI Integration

Modern systems incorporate machine learning algorithms that work with precision gear systems to adapt to surgeon preferences and optimize movements. Gear systems with integrated sensors provide the data needed for real-time AI analysis and movement refinement.

Haptic Feedback

Advanced gear configurations with embedded force sensors now enable surgeons to "feel" tissue resistance through console controls. These systems require extremely low-friction, zero-backlash gear trains to accurately transmit tactile information to the operator.

Miniaturization

Next-generation micro-gear manufacturing techniques have enabled the development of instruments under 3mm in diameter, facilitating access to previously inoperable areas. These advancements rely on precision gear cutting techniques achieving tolerances below 2 microns.

Engineering Challenges in Surgical Robot Gear Design

Despite significant advances, several key challenges remain in optimizing gear systems for surgical robotics:

Sterilization Compatibility

Gear systems must withstand repeated autoclave cycles (134°C steam, high pressure) or other sterilization methods without degradation. This necessitates specialized materials and lubricants that maintain performance through hundreds of sterilization cycles.

Backlash Minimization

Eliminating play or backlash in gear trains is essential for precision surgical tasks. Engineers employ strategies like split-gear designs, preloaded gear pairs, and precision manufacturing to achieve near-zero backlash operation.

Miniaturization Constraints

Creating effective gear systems at microscale dimensions presents manufacturing challenges. Advanced techniques like micro-EDM and laser cutting are pushing the boundaries of what's possible in miniature gear production.

Biocompatibility Requirements

Gears in patient-contact applications must meet rigorous biocompatibility standards. This often necessitates specialized materials and surface treatments that may have different mechanical properties than optimal gear materials.

Balancing Precision and Cost

Ultra-precision gears significantly impact system costs. Designers must balance performance requirements against economic considerations to create viable commercial systems accessible to healthcare providers.

Reliability Demands

Surgical robot gear systems must maintain precision over thousands of operating hours with minimal maintenance. This requires sophisticated testing protocols and quality control measures exceeding those of many industrial applications.

_1746586793_WNo_512d512.png)