CNC Machines and Lathes: The Critical Role of Gears

CNC machining centers and lathes bear a special mission in industrial modernization as they are the progenitors of equipment for producing all industrial components. At the heart of these sophisticated machines lies a crucial component: gears. This article explores the vital function, types, and applications of gears in CNC machining, providing insights into how they contribute to precision manufacturing.

Understanding the Importance of Gears in CNC Technology

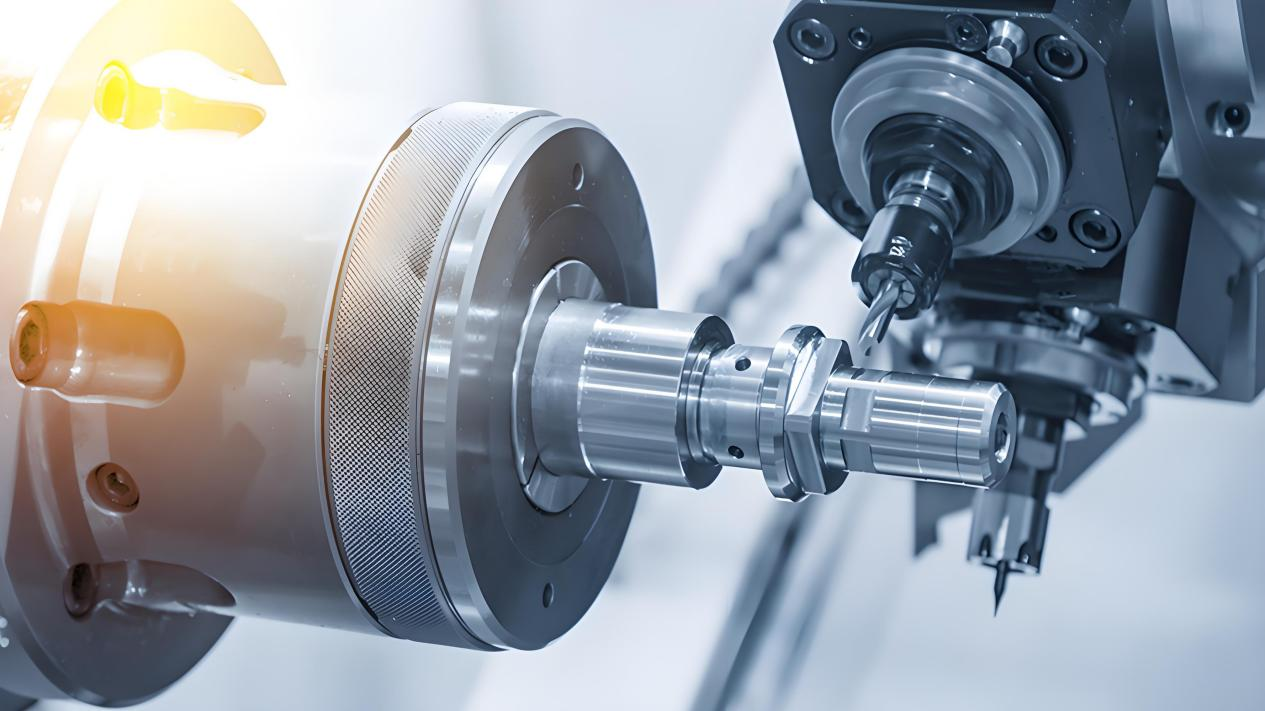

Gears are mechanical transmission components that transfer power from one shaft to another, widely used in industries such as CNC lathes. These precision-engineered components are fundamental to the operation of modern manufacturing equipment, enabling the precise control and motion that define CNC machinery.

Modern CNC machinery with sophisticated gear systems for precise motion control

In the context of computer numerical control (CNC) machines, gears serve as the mechanical backbone that translates digital instructions into physical movement. The precision of gears directly affects the manufacturing accuracy and operational efficiency of CNC lathes and machining centers, making them critical components in the production chain.

Primary Functions of Gears in CNC Machines and Lathes

Power Transmission

Gears efficiently transfer power from motors to various mechanical components, minimizing energy loss while maintaining consistent torque throughout the system. This ensures reliable operation even during demanding cutting operations.

Speed and Torque Adjustment

Through careful gear ratio selection, CNC machines can achieve optimal balance between speed and torque for different operations. This adaptability allows a single machine to perform diverse machining tasks with varying requirements.

Lead Screw Operation

Gears control the rotation of lead screws which convert rotational motion into linear movement. This mechanism enables the precise positioning of cutting tools and workpieces essential for high-precision manufacturing.

Beyond these primary functions, gears in CNC systems also contribute to vibration damping, backlash compensation, and overall system stability. The interdependence of these functions highlights why gear quality and selection are paramount considerations for machine builders and maintenance engineers.

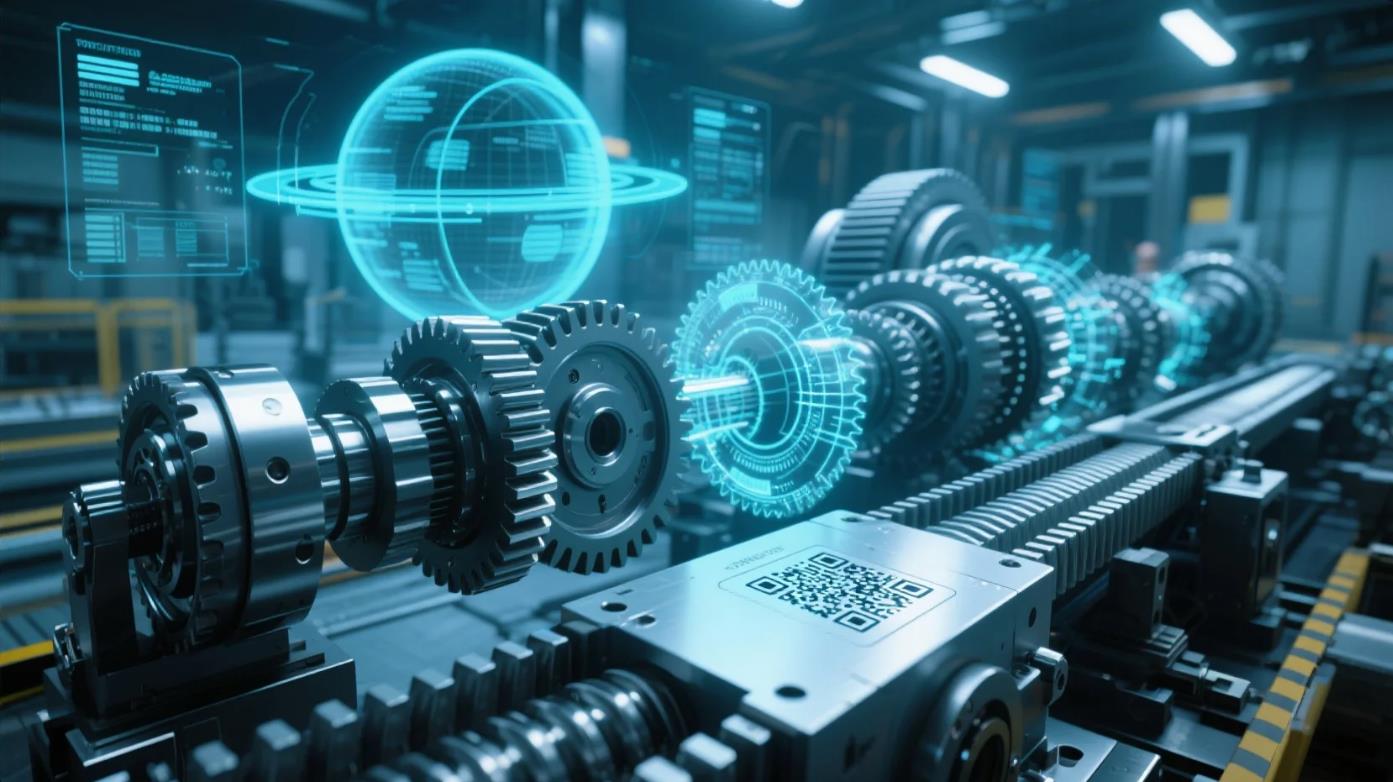

Types of Gears Used in CNC Machinery

Modern CNC machines incorporate various gear types, each selected for specific performance characteristics and applications. Understanding these distinctions helps in appreciating the engineering considerations behind CNC design.

| Gear Type | Primary Application | Advantages |

|---|---|---|

| Spur Gears | Main drive systems | High efficiency, simple design, cost-effective |

| Helical Gears | High-speed transmissions | Smoother operation, reduced noise, higher load capacity |

| Bevel Gears | Angular power transmission | Efficient power transfer between non-parallel shafts |

| Worm Gears | High reduction ratios | Compact design, high torque multiplication, self-locking capabilities |

| Rack and Pinion | Linear motion systems | Direct conversion of rotary to linear motion, precise positioning |

Various gear types employed in modern CNC machining systems

The Impact of Gear Precision on CNC Performance

The precision of gears in CNC machines directly influences several key performance metrics:

Machining Accuracy

High-precision gears with minimal pitch errors ensure accurate tool positioning, directly affecting the dimensional accuracy of manufactured parts.

Surface Finish Quality

Smoother gear operation reduces vibration during machining, resulting in superior surface finishes on manufactured components.

Tool Life

Precision gears reduce uneven loads and vibrations on cutting tools, extending tool life and reducing replacement costs.

Energy Efficiency

Well-designed gear systems minimize friction and energy losses, reducing power consumption and operational costs.

Advanced CNC machines often incorporate gear quality grades ranging from Q7 to Q12 (AGMA standards), with higher precision applications requiring higher grade numbers. The investment in premium gear components typically yields returns through improved part quality and reduced maintenance costs.

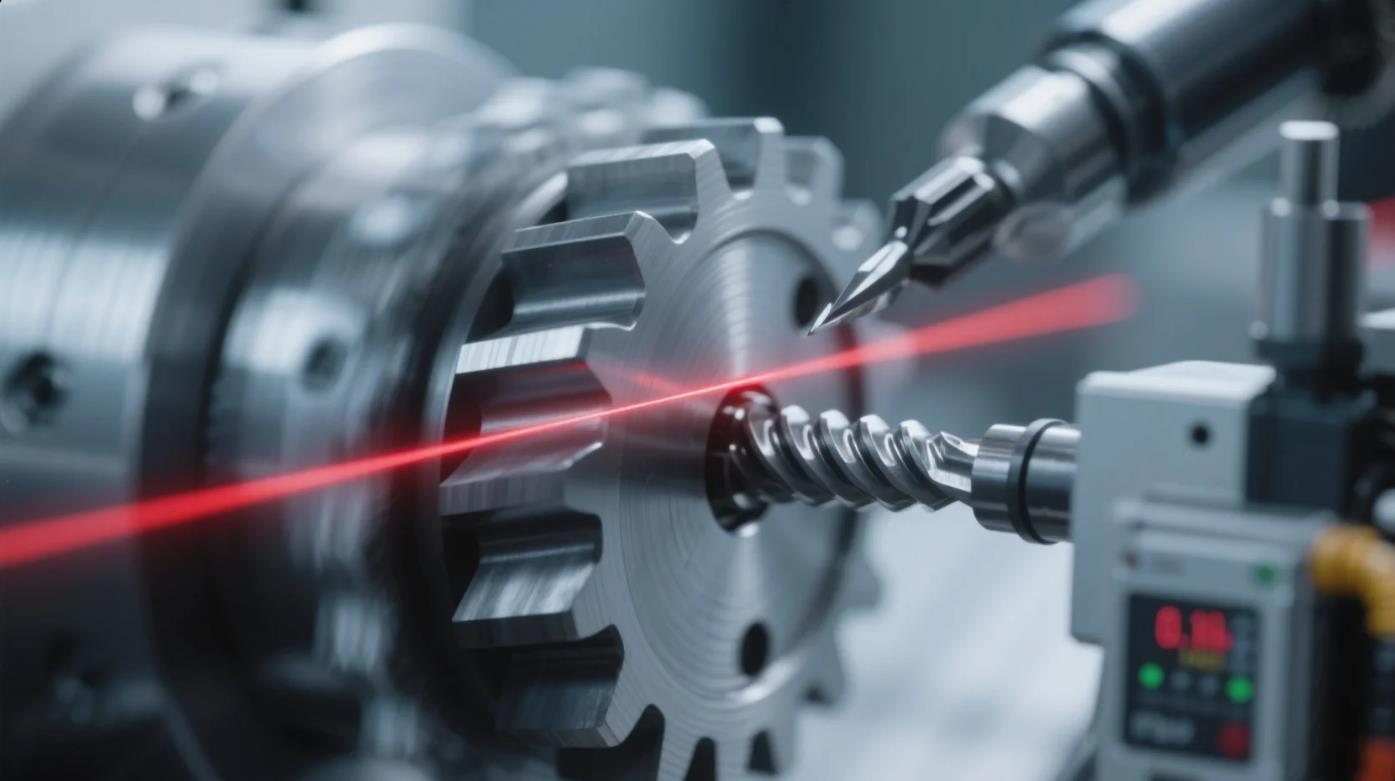

Gear Manufacturing for CNC Applications

Ironically, high-precision gears for CNC machines are themselves often manufactured using CNC technology, creating a self-reinforcing cycle of precision. Modern gear production methods include:

CNC Gear Hobbing

A highly efficient process for producing external gears, splines, and sprockets. The hobbing tool and workpiece rotate continuously in a synchronized relationship, progressively cutting the gear teeth profile.

CNC Gear Shaping

Particularly useful for cutting internal gears or gears with shoulders that would interfere with the path of a hob. The shaper cutter reciprocates as both it and the workpiece rotate.

CNC Gear Grinding

A finishing process that achieves the highest precision. After heat treatment, gear grinding corrects any distortions and produces extremely accurate tooth profiles with excellent surface finish.

CNC gear manufacturing process showing precision hobbing operation

Maintenance and Inspection of CNC Machine Gears

Regular maintenance of gear systems in CNC machines is essential for maintaining precision and extending machine life. Industry best practices include:

- Regular lubrication with appropriate gear oils or greases specified by the manufacturer

- Periodic backlash inspection and adjustment to maintain positioning accuracy

- Vibration analysis to detect early signs of gear wear or damage

- Visual inspection for signs of tooth wear, pitting, or cracking

- Monitoring of gear noise patterns which can indicate developing problems

- Gear alignment checking using precision measurement instruments

Modern maintenance approaches increasingly incorporate predictive techniques, where embedded sensors monitor gear performance in real-time, allowing for intervention before failures occur. This proactive approach significantly reduces costly downtime in production environments.

Advancements in Gear Technology for CNC Applications

The evolution of gear technology continues to enhance CNC machine capabilities. Recent innovations include:

Advanced Materials

Special steel alloys, powder metallurgy gears, and carbon-fiber reinforced composites offer improved strength-to-weight ratios and durability.

Surface Treatments

Nitriding, carburizing, and PVD coatings significantly enhance wear resistance and extend gear service life in demanding applications.

Optimized Tooth Profiles

Computer-optimized involute profiles and modified tooth geometries reduce noise, increase load capacity, and improve efficiency.

Direct Drive Technology

In some high-end CNC applications, direct drive motors eliminate traditional gear trains, offering unprecedented precision and responsiveness.

Selecting the Right Gears for CNC Applications

When specifying gears for CNC machines or retrofitting existing equipment, several key factors should be considered:

| Factor | Considerations |

|---|---|

| Load Requirements | Maximum torque, continuous operating loads, shock loading conditions |

| Speed Requirements | Maximum RPM, variable speed needs, acceleration/deceleration profiles |

| Precision Grade | Required positioning accuracy, surface finish requirements |

| Environmental Conditions | Presence of cutting fluids, chips, dust, temperature variations |

| Noise Limitations | Workplace noise restrictions, precision requirements |

| Service Life Expectations | Expected operational hours, maintenance intervals |

Working with specialized gear manufacturers who understand CNC applications can help in selecting optimized components that balance performance requirements with budget constraints.

Optimize Your CNC Machinery Performance with Precision Gears

Whether you're designing new CNC equipment, retrofitting existing machinery, or establishing maintenance protocols, understanding the critical role of gears can significantly impact your manufacturing outcomes. Contact gear specialists to discover how advanced gear solutions can enhance your CNC operations.

Conclusion: The Future of Gears in CNC Technology

As CNC technology continues to evolve, the role of gears remains fundamental despite advancements in direct drive systems and electronic controls. Future trends point toward hybrid systems that combine the best of mechanical gear precision with advanced electronic compensation.

The integration of IoT sensors with gear systems promises predictive maintenance capabilities that will further reduce downtime and extend machine life. Additionally, advancements in materials science continue to improve gear performance in extreme conditions.

For manufacturing enterprises investing in CNC technology, understanding the critical role of gears in these sophisticated machines helps in making informed decisions about equipment selection, maintenance protocols, and upgrade pathways. The precision of gears directly influences manufacturing accuracy, operational efficiency, and ultimately, the quality of produced components.