Automation and the Role of Gear Systems

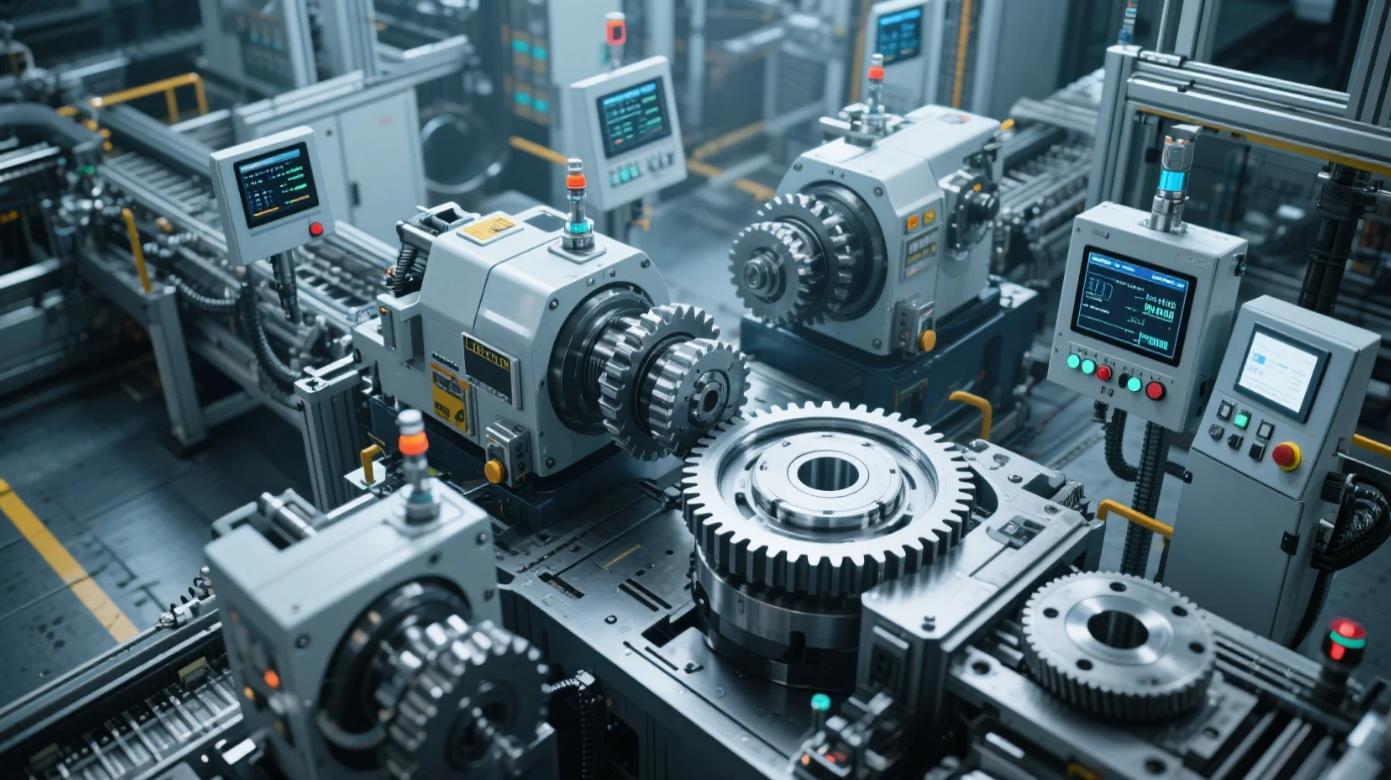

With the advent of the Fourth Industrial Revolution, the global manufacturing industry is undergoing a fundamental transformation toward digitization, networking, and intelligence. Technologies such as big data, artificial intelligence, 5G, and visual recognition are reshaping how automation enterprises operate and deliver services, becoming new engines of growth.

With the advent of the Fourth Industrial Revolution, the global manufacturing industry is undergoing a fundamental transformation toward digitization, networking, and intelligence. Technologies such as big data, artificial intelligence, 5G, and visual recognition are reshaping how automation enterprises operate and deliver services, becoming new engines of growth.

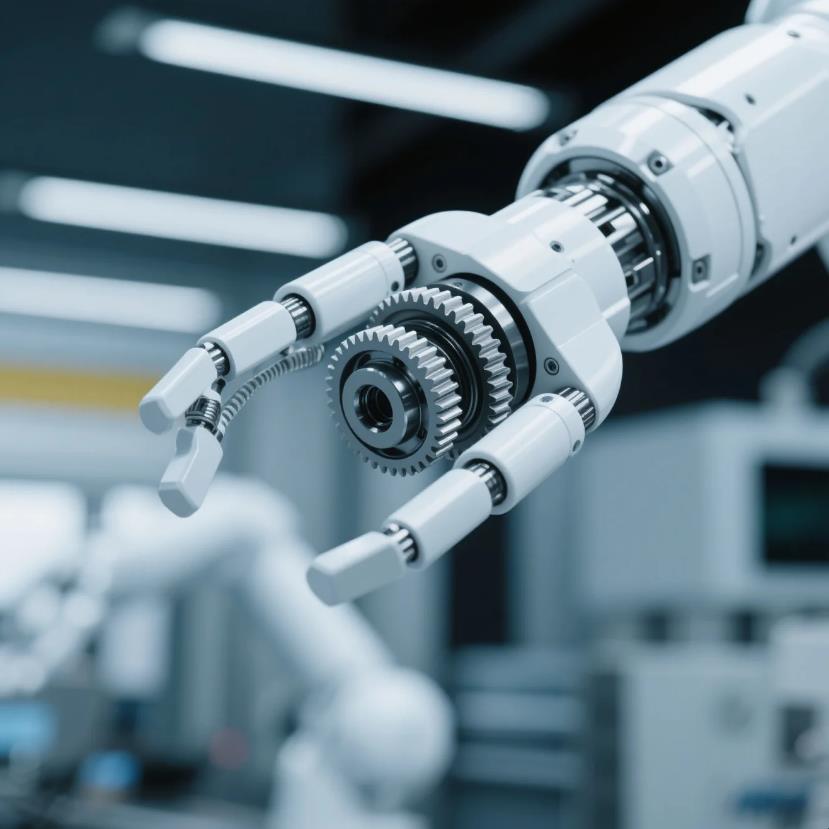

Smart factories rely on high-precision gears to maintain efficiency in fully automated production lines.

The Critical Role of Gears in Automation

Gear systems—along with timing pulleys and belts—are foundational in automation. They enable precise and reliable power transmission, ensuring that mechanical systems operate with optimal accuracy and efficiency. From conveyor systems in smart factories to robotic arms in high-speed assembly lines, gears are essential components.

Gear systems—along with timing pulleys and belts—are foundational in automation. They enable precise and reliable power transmission, ensuring that mechanical systems operate with optimal accuracy and efficiency. From conveyor systems in smart factories to robotic arms in high-speed assembly lines, gears are essential components.

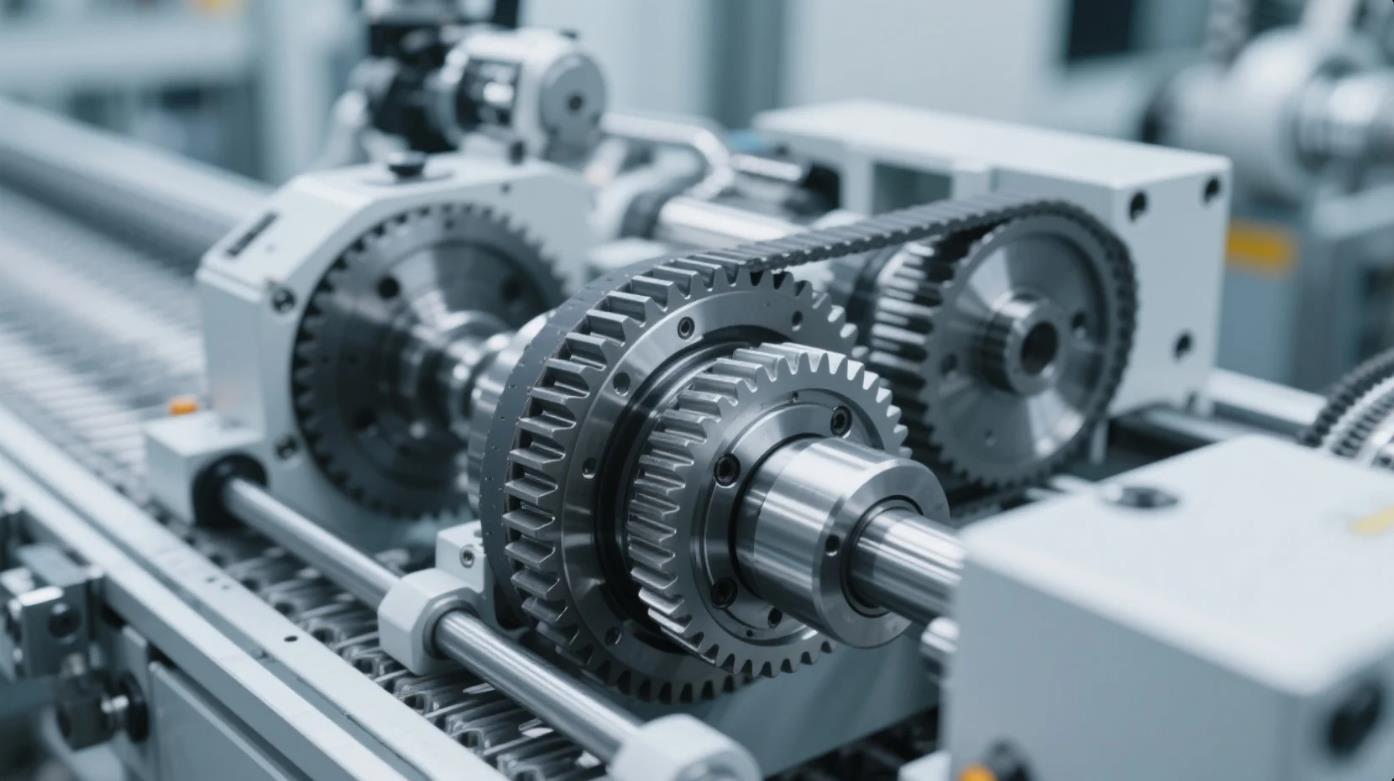

A close-up view of a precision gear transmission system used in modern automation machinery.

Why Precision Gears Matter

-

Enhanced Efficiency: Reducing energy loss and maximizing productivity through smooth transmission.

Enhanced Efficiency: Reducing energy loss and maximizing productivity through smooth transmission. -

High Precision: Essential in robotic and CNC machinery for consistent, repeatable motion control.

High Precision: Essential in robotic and CNC machinery for consistent, repeatable motion control. -

Durability and Longevity: Industrial-grade gears are engineered to withstand demanding environments and continuous operations.

Durability and Longevity: Industrial-grade gears are engineered to withstand demanding environments and continuous operations. -

Modular Design: Gears offer flexibility in component replacement and upgrades in complex automation systems.

Modular Design: Gears offer flexibility in component replacement and upgrades in complex automation systems.

Real-World Applications of Gears in Automation

Gears play an integral part in various automation fields, including:

Gears play an integral part in various automation fields, including:

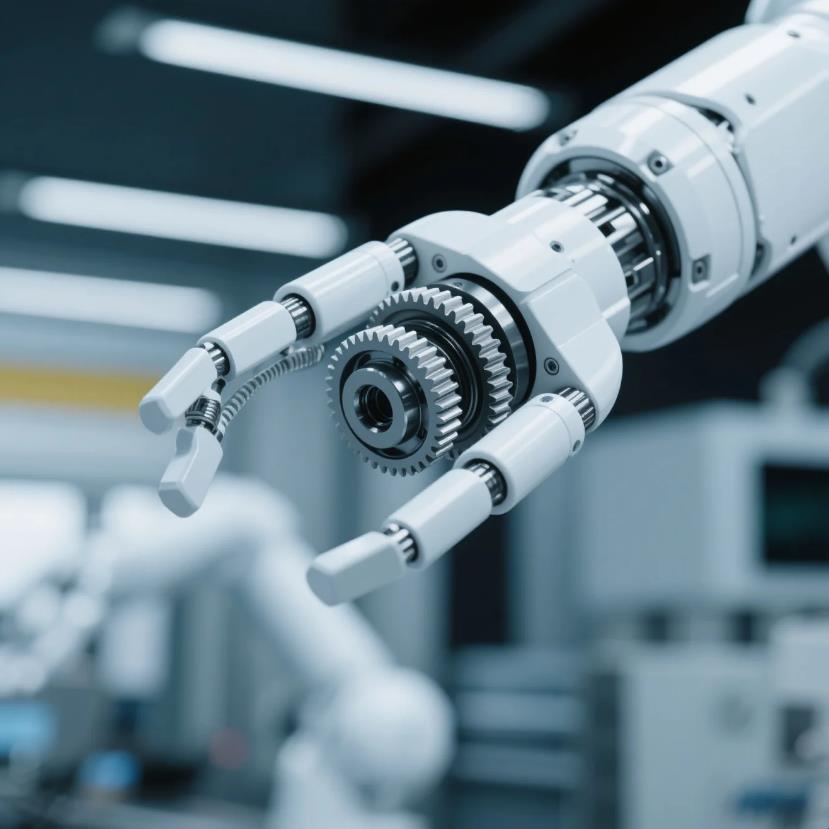

Robotics

Robotics

Precision gears ensure smooth, responsive movement in robotic joints, critical for accuracy and safety.

Material Handling

Material Handling

Gear motors drive conveyor belts and lifting systems, facilitating seamless logistics and warehouse automation.

CNC Machinery

CNC Machinery

Gears help deliver precision in cutting, milling, and drilling operations by maintaining speed and torque control.

The Future of Gears in Automation

As smart manufacturing and AI-driven production lines evolve, the demand for high-performance gear solutions will only grow. Gears will continue to play a key role in enabling end-to-end automated production, ultimately helping businesses achieve higher returns and operational excellence.

As smart manufacturing and AI-driven production lines evolve, the demand for high-performance gear solutions will only grow. Gears will continue to play a key role in enabling end-to-end automated production, ultimately helping businesses achieve higher returns and operational excellence.

Driving Innovation Through Gear Technology

Whether it’s a smart factory upgrading its automated lines or a robotics manufacturer improving system responsiveness, precision gear technology is at the heart of modern automation. At the intersection of mechanics and innovation, gears empower industries to build faster, smarter, and more sustainable systems.

Whether it’s a smart factory upgrading its automated lines or a robotics manufacturer improving system responsiveness, precision gear technology is at the heart of modern automation. At the intersection of mechanics and innovation, gears empower industries to build faster, smarter, and more sustainable systems.